It is important for the proper functioning of your engine that the spark plugs are tightened properly. The correct torque setting will ensure an optimal combustion process, reduce wear, and tear, and prevent engine damage. This guide will explain all the factors you need to consider when tightening your spark plugs and provide step-by-step instructions for doing it correctly.

Tools and Materials Needed

Before you begin the job of tightening your spark plugs, make sure you have all the tools and materials needed to complete it. You will need a new set of spark plugs, a ratchet with a deep well socket that fits them, an anti-seize compound or thread locker adhesive (optional), a torque wrench (optional), and gloves to protect your hands.

Factors That Affect How Tight You Should Make A Spark Plug

Several factors can influence how tight you should make a spark plug: The type of threads in the engine head, the type of material used in the plug itself, how long the plug has been used before being replaced, what kind of temperature range it is designed for and if any anti-seize compounds or thread locker adhesives were used when installing them. All these factors must be considered for proper spark plug installation.

Instructions for Properly Tightening A Spark Plug

Follow these steps to ensure that your spark plug is properly tightened:

-

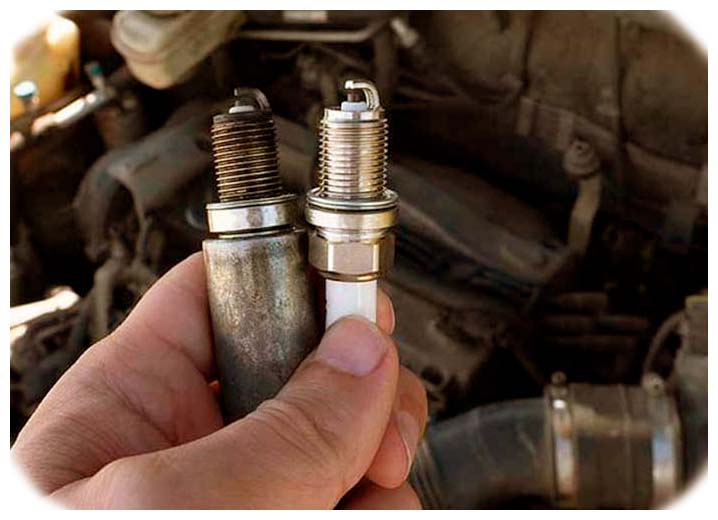

Step 1 – Remove the Old Spark Plug: Use the ratchet with a deep well socket and carefully unscrew the old spark plug from the engine head. Be sure to clean off any debris or dirt around the threads before installing a new spark plug.

-

Step 2 – Apply Anti-Seize Compound To The Threads Of The New Plug: This will help prevent corrosion and make it easier to unscrew in the future when it needs to be replaced again. If you are using thread locker adhesive, apply this before installing the plug as well.

-

Step 3 – Install The New Plug In The Engine Head: Put the new spark plug into place and hand tighten it down firmly with a ratchet, making sure not to over-tighten as this can damage both your engine and spark plugs themselves.

-

Step 4 – Hand-Tighten The Plug Down Firmly With A Ratchet: Use a torque wrench if possible to ensure that you are tightening your spark plugs correctly, according to manufacturer specifications or local regulations (if applicable). If no torque wrench is available, make sure to tighten the spark plugs firmly but not excessively.

Signs Of An Improperly Installed Spark Plug

There are a few signs that you can look for if you suspect that your spark plug has been improperly installed. These include engine misfires, poor acceleration, backfiring, and/or decreased performance. If any of these symptoms appear after installation, double-check to ensure the spark plugs were properly tightened as this may be the cause of the problem.

Conclusion

Knowing how to properly tighten your spark plugs is essential for optimal engine performance and reducing wear and tear. Be sure to follow the steps outlined in this guide and use the right tools and materials when installing them. Taking the time to do it correctly now could save you time and money in the future.

Step 1 – Remove the Old Spark Plug: Use the ratchet with a deep well socket and carefully unscrew the old spark plug from the engine head. Be sure to clean off any debris or dirt around the threads before installing a

Step 1 – Remove the Old Spark Plug: Use the ratchet with a deep well socket and carefully unscrew the old spark plug from the engine head. Be sure to clean off any debris or dirt around the threads before installing a

Add Comment