The crank sensor is an important component of your vehicle’s engine but can be hard to find. Its location depends on the type of vehicle you have. Knowing where to find your vehicle’s crank sensor can help you diagnose any issues arising from its malfunction. In this article, we’ll discuss what a crank sensor is, where it’s typically located, and how it affects engine performance.

What Is a Crank Sensor?

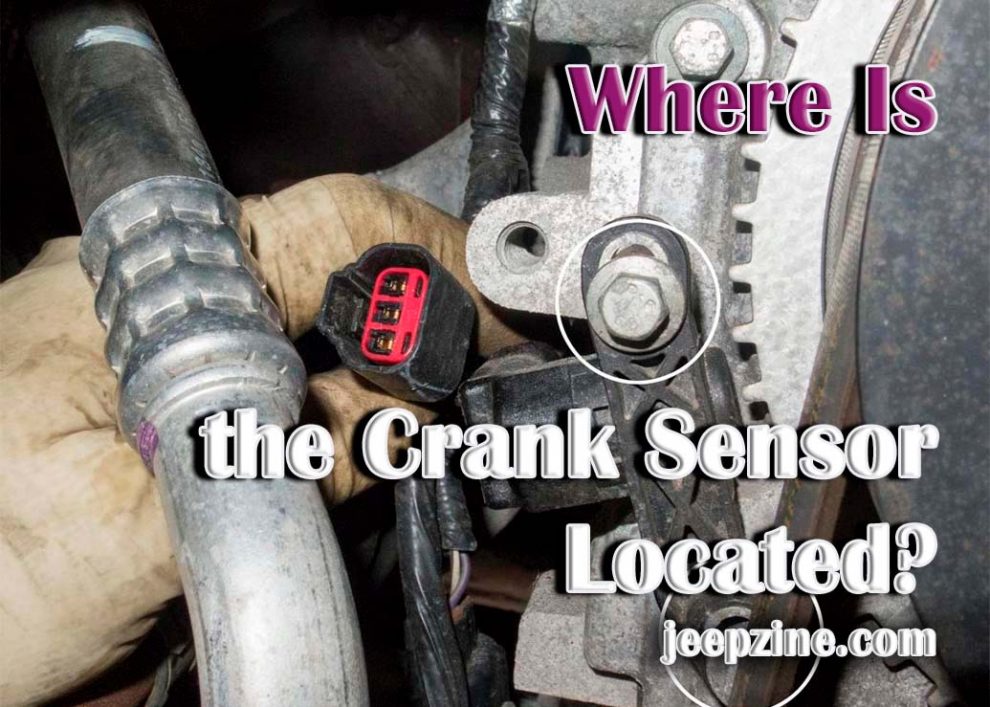

Where Is the Crank Sensor Located?

The crank sensor is typically located at the front or rear of your engine.

In Front-Wheel Drive Vehicles: In front-wheel drive vehicles, the crank sensor is usually located on the side or underside of the engine block, near where the transmission meets it. It is generally mounted in a metal bracket and can be accessed by removing a few bolts.

In Rear-Wheel Drive Vehicles: In such vehicles, the crank sensor is typically found at the back of the engine near where it connects to the transmission. Some cars also have crank sensors mounted at an angle facing downward towards where it connects to its harness. It should be easy to spot as it is connected with a wiring harness and may have protective shielding.

How Does a Crank Sensor Affect Performance?

A crank sensor plays a critical role in the overall performance of an engine. Here are a few ways in which a crank sensor affects performance:

-

Timing and Ignition Control: The crank sensor provides the engine control unit (ECU) with precise information about the position and speed of the crankshaft. This data enables the ECU to determine the optimal fuel injection and ignition timing accurately. Proper timing ensures efficient combustion, maximizing power output and fuel efficiency. If the crank sensor fails or provides inaccurate readings, it can lead to misfires, poor fuel economy, and reduced engine performance.

-

Fuel Injection Synchronization: In engines equipped with electronic fuel injection systems, the crank sensor helps synchronize fuel injection with the crankshaft’s position. It ensures fuel is correctly delivered to the cylinders during the engine’s four-stroke cycle. If the crank sensor malfunctions, it can disrupt the fuel injection process, resulting in rough idle, hesitation, or a loss of power.

-

Engine Misfire Detection: The crank sensor is instrumental in detecting engine misfires. By monitoring the rotational speed and position of the crankshaft, the sensor can identify any irregularities or inconsistencies in the engine’s firing sequence. When a misfire occurs, the ECU can adjust the fuel mixture or ignition timing to rectify the issue and maintain optimal engine performance.

-

Speed and RPM Calculation: The crank sensor also provides data on the engine’s rotational speed, allowing the ECU to calculate the engine’s revolutions per minute (RPM). This information is essential for various engine control functions, such as shifting points in automatic transmissions, activating certain vehicle systems, and providing input to the vehicle’s speedometer.

A properly functioning crank sensor is crucial for maintaining optimal engine performance. It ensures accurate timing, efficient fuel delivery, and reliable combustion, improving power, fuel efficiency, and overall drivability. If a crank sensor develops faults or malfunctions, it can negatively impact performance, reducing power, rough running, or even engine stalling.

Conclusion

The crank sensor is an essential component of modern automotive engines. Its location depends on the type of vehicle you have, typically being found at the front or rear of the engine block. The crank sensor monitors the rotational position and speed of the crankshaft, enabling accurate fuel injection and ignition timing. It also helps diagnose misfires and calculate engine RPMs. If a crank sensor fails or malfunctions, it can lead to poor performance, reduced fuel efficiency, and even engine stalling. Knowing where to look for your vehicle’s crank sensor will help you quickly identify any issues.

Fuel Injection Synchronization: In engines equipped with electronic fuel injection systems, the crank sensor helps synchronize fuel injection with the crankshaft’s position. It ensures fuel is correctly delivered to the cylinders during the engine’s four-stroke cycle. If the crank sensor malfunctions, it can disrupt the fuel injection process, resulting in rough idle, hesitation, or a loss of power.

Fuel Injection Synchronization: In engines equipped with electronic fuel injection systems, the crank sensor helps synchronize fuel injection with the crankshaft’s position. It ensures fuel is correctly delivered to the cylinders during the engine’s four-stroke cycle. If the crank sensor malfunctions, it can disrupt the fuel injection process, resulting in rough idle, hesitation, or a loss of power.

Add Comment